(Skip to the very bottom if you want the instructions on how to use this hose.)

I finally have a new dishwasher installed (more details later). Thanks to instruction defects on Home Depot’s GE Universal 6′ Dishwasher Connector, the installation was significantly lengthened.

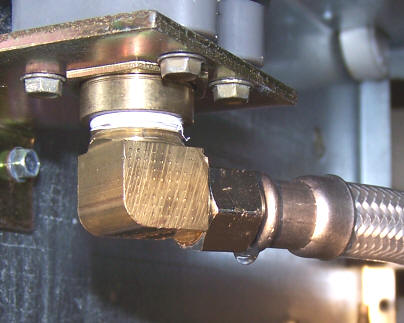

The first of these hoses leaked out of both ends:

This is what the end looked like when I was done with it:

I returned it as defective and got another one. The second one also leaked:

…out both ends!

Notice that this time, I used Teflon. Didn’t help.

What is going on? I double checked the instructions:

…and couldn’t find where I went wrong.

Note how the instructions say “DO NOT OVERTIGHTEN.” What in tarnation does that mean? Thanks for being so helpful and specific, GE!

Here’s what I did:

- Hand tightened.

- Wrench tightened until the nut doesn’t back off after I remove the wrench. Before that point, the nut would back itself up about 1/32 to 1/16 turn when I left off the wrench.

- Turned on the water.

- Watched both fittings leak.

- Throw tools around the room and curse Home Depot and GE.

- Storm around the house in a rage, pulling out my hair and banging my head on light switches and doorknobs.

- Tightened each fitting about 1/8 – 1/4 turn at a time until the leak stopped. Except neither leak stopped, leading to…

- Eventually bottomed out each fitting to where I couldn’t tighten any more.

I didn’t think I was overtightening in step 2, but I’m sure that it was way overtightened by step 8.

Back at Home Depot the third time, I asked the resident certified plumber what I was doing wrong. He said I need to get it pretty tight. (Gee, thanks, hadn’t that method failed me twice already‽)

Doing the same wrong thing over and over again is insanity, so I thought I would try a new tactic this time. I followed the same instructions that came with some faucet hookups: hand tighten, then turn a wrench an additional quarter turn.

Hand tightening got difficult because the 3/8″ fitting fit had smooth sides and fit in a 5/8″ wrench. But I did it that way on both ends, and it held! And didn’t leak!

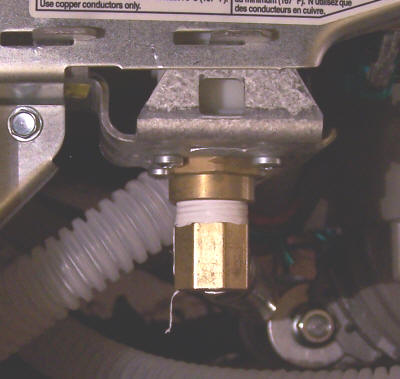

Here is the under-sink fitting:

…and the under-dishwasher connection:

My gentle readers may wonder, “Aren, don’t you feel guilty returning a product that you screwed up?”

No. This is a product defect. Part of a product is its instructions. The fancy packaging clearly denotes this as a DIY-oriented product. Therefore, the instructions should be appropriate for DIY types like me who have never done this before. Simply stating “DO NOT OVERTIGHTEN” when you really mean “hand tighten and then wrench tighten an additional quarter turn” is a gross defect in the instructions.

Another part of the product is the design. There is no need for the flat edges on the nut to engage the wrench. If the nut had been enlarged and equipped with a grip-able surface, then no wrenches would be needed at all. Human strength would be able to provide enough torque.

DIY people are used to fittings where you need to crank them reasonably tightly. Almost all copper fittings are that way, almost all metal-to-metal fittings in a car are that way (except for Vortec intake manifold bolts when you use the plastic manifolds!), etc. Home Depot should have done a better job of policing its products, especially for one that’s 50% more than the equivalent at Lowe’s.